In the Field

Robotic house-printing isn’t just a flashy proof of concept anymore—it’s industrialized real estate. Systems capable of printing everything from foundations to roofs are moving from pilot sites to livable communities, reshaping construction with autonomy and precision.

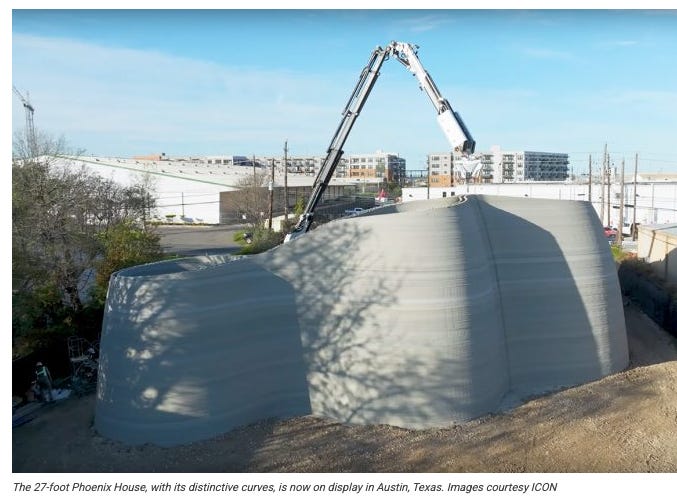

Phoenix & Vulcan: ICON's Robotic Gantries

ICON’s Vulcan gantry printer and next-gen Phoenix boom arm are full-structure robotics platforms—capable of delineating walls, infrastructure embeds, and even roofs.

Vulcan covers ~280 m² at 5–7 in/min using proprietary Lavacrete via BuildOS.

Phoenix extends to multi-story builds, reinforces with wire extruders, halves setup time, and slashes cost-per-square-foot to ~$25–80.

These systems have already fabricated homes in Phoenix and Georgetown and are now building a 43-unit desert hotel in Marfa, Texas.

Global Players Hitting Field Deployments

Apis Cor: A newer player in construction robotics, Apis Cor is just beginning to deploy its portable 3D-printing robots in the U.S. and internationally. The company gained global attention by winning NASA’s 3D-Printed Habitat Challenge with SEArch+, showcasing its innovation in autonomous habitat construction. While Apis Cor’s commercial projects are still emerging, their technology and NASA win mark them as a company to watch.

Luyten 3D: Delivered a functional two-story print in Australia in 32 hours using the AI-enabled Platypus X12.

WASP: Italy’s bio-material robotic printing lab printed the TECLA house from clay with modular dual-gantry arms.

Challenges

While 3D printing homes is often celebrated for its speed and innovation, not everyone is convinced the technology is ready to revolutionize construction. In the popular YouTube video "Why 3D Printing Buildings Leads to Problems," Stewart Hicks outlines several hurdles that remain for large-scale adoption.

“There’s quite a few challenges that are getting in the way, and frankly, the buildings made like this... they look a little weird. Companies across the world are trying to solve these problems by racing to make the process scalable, affordable, sustainable, and palatable to people that would just prefer living in a more traditional looking home.”- Stewart Hicks, Architectural Design Educator

Hicks points out that 3D-printed structures face design and material limitations. For example, unlike bricks, 3D-printed concrete can’t easily create sharp 90-degree corners, often resulting in curvy exterior shapes. Openings for doors and windows require extra support, and the tolerance for construction errors is much tighter than in traditional building—meaning small mistakes can have big consequences. Integrating standard building components, like windows and cabinetry, into the uneven surfaces of printed walls can be difficult, leading to gaps or awkward finishes.

He also highlights practical concerns about maintenance and flexibility:

“If anything happens to the 3D printed part of the structure, it’s almost impossible to repair it back to its original state. What are you going to do, bring out that giant machine? Additions or renovations are all the same thing.”1

Finally, Hicks notes that most 3D printing companies are highly vertically integrated, making it hard for outside architects or builders to work with the technology or modify printed homes in the future. For now, he argues, these challenges mean 3D-printed buildings are still a work in progress, with important questions left to answer before they become a mainstream solution.

Closing Reflection

I find these 3D-printed homes completely fascinating. The idea that a robotic system can fabricate a real, livable structure—walls, roof, and all—is awe-inspiring. But what excites me even more is the idea of living in one.

As an environmentalist, I like the “green” aspect of these homes. (Or, maybe “greener” is a more accurate term.)

3D-printed homes can:

Drastically reduce material waste, since extrusion systems use only what’s needed.

Use low-carbon materials, like ICON’s Lavacrete or WASP’s clay-based compounds.

Minimize transportation emissions by building on-site from local or modular inputs.

Lower energy consumption during production compared to traditional construction.

Enable passive, efficient designs thanks to complex curves and insulating geometries.

At the same time, I’m fully aware that these systems still face challenges—whether it’s tolerance for error, integrating standard parts, or scalability. As Stewart Hicks points out, 3D-printed homes can feel unfamiliar to traditional tastes, and retrofitting or repairs raise real issues.

Still, I remain optimistic. These hurdles don’t diminish the potential—they sharpen the focus. If robotic construction can overcome them, we won’t just be printing homes. We’ll be prototyping a better relationship between people, machines, and the built environment.

#Robotics #3DPrinting #ConstructionTech #AutonomousSystems #BuildOS #ICON #DigitalTwins #ArchitectureAutomation #FutureOfHousing #DROIDs

Share this post